BIOPLASTICS IMPORTANCE

This material is named NonOilen® according to the polymer base. The monomers were not isolated from the fossil source (from oil, therefore “non-oil”), but it comes from 100 % of renewable resources.

wHY ARE BIOPLASTICS IMPORTANT?

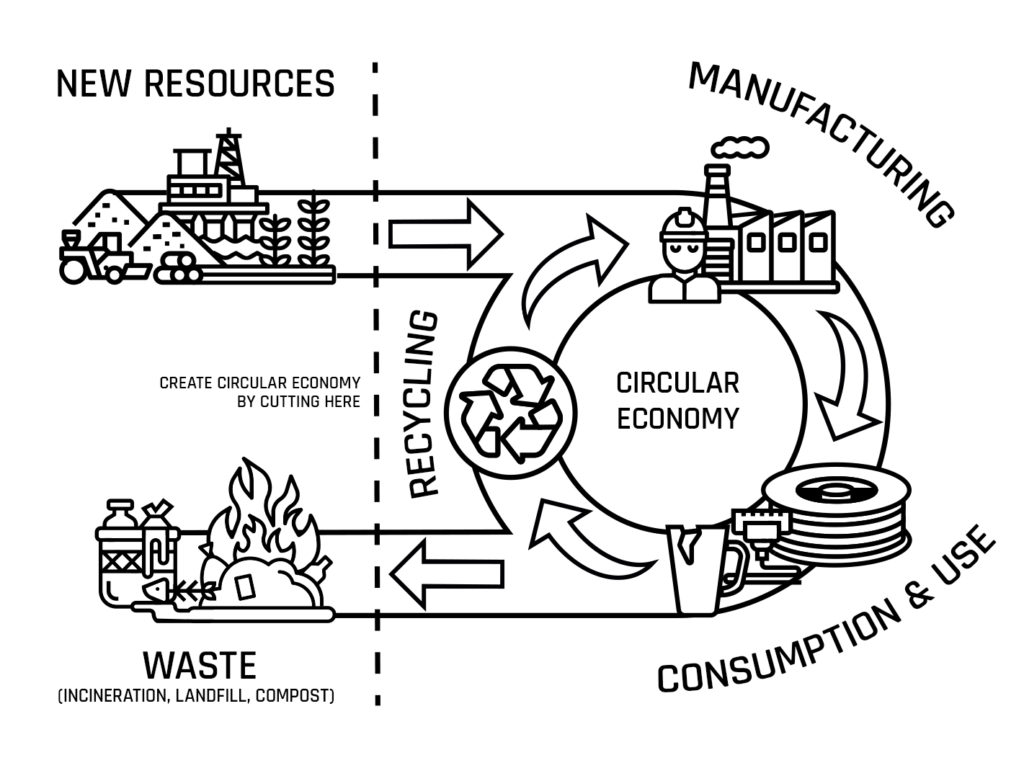

The circular economy comes with the concept of 3R, or R3. It means to Reduce, Reuse, Recycle. We need to reduce the waste, so many materials are used only once and thrown away – we must reuse them as many times as we can. We need to think about our actions and prevent waste (for example use tap water instead of buying many bottles or prefer choosing bigger packages). And once the reused object comes into the form of unused waste, we need to recycle the material. If we will follow these principles, we can cut the external new resources and function according to this scheme:

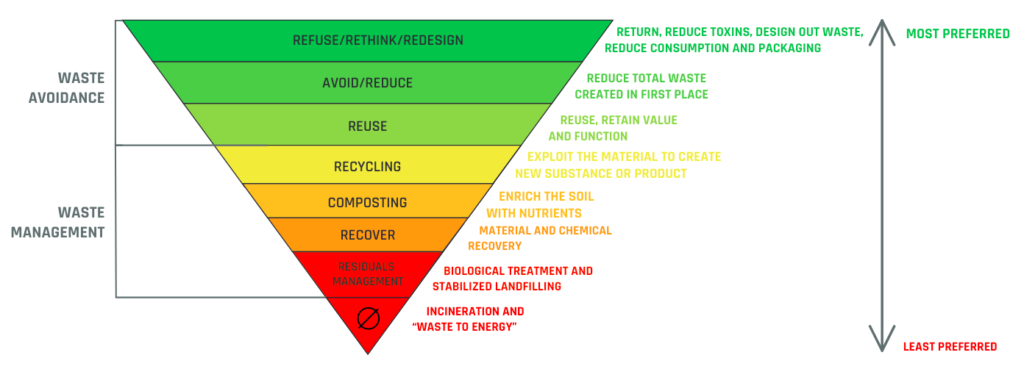

The main principle is called “zero waste hierarchy“. It is clearly expressed in the picture below.

NOT THIS WAY

The first try to improve the biodegradability of commodity plastics was by oxo-bioplastics. The standard polymers (like PE, PP, PS) were modified by the addition of substances which cause oxo-degradation of those polymers. But they cannot be appropriately degraded in compost. They are disintegrated at small particles under 2 mm (the pieces of non-biodegraded polymer), but these small pieces and secondary microplastics (primary microplastics are made on purpose, but secondary ones are created by the degradation of plastics) harm our environment in the soil or in water. Plus, it is against the core principles of the circular economy, the oxo-plastics form a lot of disposable goods, they are used once, they cannot be recycled without the loss of properties, they degrade already while used (in the presence of oxygen). They are referred as biodegraded, but when they are placed into compost, they cannot be degraded appropriately.

As oxo-bioplastics are not helping to save the environment, but do exactly opposite, it is necessary to find different ways to influence the impact on the environment. In general, we need to:

find new ways to degrade the polymers (for example chemical)

find new sources to replace fossil resources

find new resources to create biodegradable polymers with high-value use

improve the handling with waste – no material should get into soil or water. The plastics have a bad reputation because they are seen as waste in the soil, in the oceans, because they can’t be degraded in less than hundreds of years there. BUT the metals, the glass, or the ceramics neither!

Even if we would create new material that can be biodegraded in soil, in the ocean, it doesn’t mean that we can throw away all the stuff after one use, or that we can throw it wherever we want. The soil has also limited capacity. The ocean should not contain any of these objects, it is dangerous for the organisms before it degrades, it takes some time.

recycle the materials unless it is more harmful to the environment than composting

find more green sources of energy (renewable sources)

improve the process of waste separation (recognition of bioplastics & composting or recycling of standard thermoplastics instead of combustion)

Bioplastics

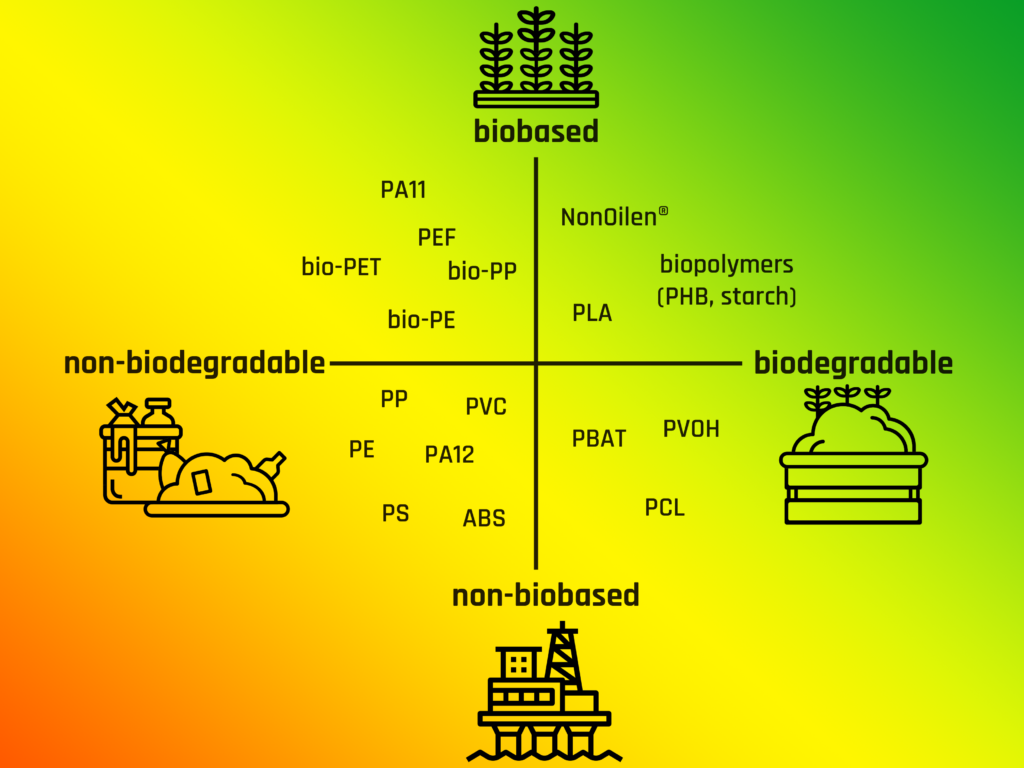

It is macromolecule that is prepared by human processing from the natural sources (biomass), such as PLA, bio-PE, PBAT, bio-PET. Mostly, it is bio-based, but not biodegradable.

It is necessary to pay attention on the designation from the companies. Under this designation, the producers may also hide plastics that contain less than 100 % of bio-based component. It can be only modified with 15 or 30 % (for example bio-PE). There are also plastics, that are 100% bio-based, but they can’t be biodegraded because of the created structure (for example polyamide 11). But on the opposite, we can find the polymers, that are biodegradable regardless of being fossil-based (like polycaprolactone).